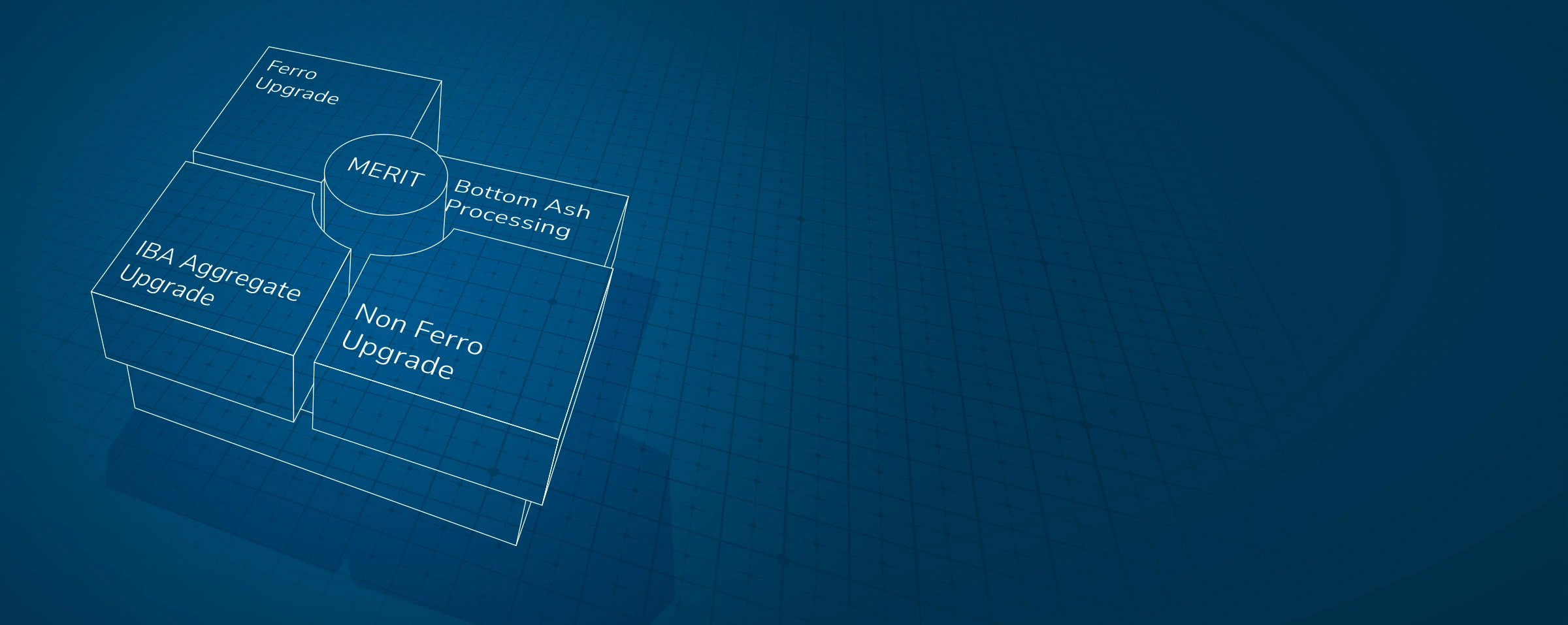

View our 3D simulation about MERIT

New opportunities for metal recovery and metal recycling

REMEX is the industry leader in technology and innovation for incinerator bottom ash processing. The group bundles its know-how across this specialised field in the form of a modular concept comprising five technical elements, reaching from the central ash processing unit to the recovery and upgrade of ferrous and non-ferrous metals as well as the production of high-quality aggregates from mineral ash. Unique to the market is our new Non-Ferro technology called MERIT, which stands for the optimised recovery of valuable non-ferrous metals. Here, we combine experience gained over the past decades, creating additional value and new business models for our national and international customers.

View our 3D simulation about MTF

REMEX technologies have a proven track record of reducing landfilling and protecting natural resources. We actively support Zero-Waste strategies by recovering sustainable minerals and metals from waste. Learn more at sustainability.remex.de